|

The 'Butters' Crane |

|||

|

Dowlais Works, Merthyr Tydfil. |

|||

|

|||

|

"Butters" Mould Breaking Crane being comissioned - June 1959 (Photograph courtesy of the John Owen Collection) |

|||

|

"Butters" Mould Breaking Crane - 2nd September 1959 (Photograph courtesy of the John Owen Collection) |

|||

|

'Butters' Mould Breaking Crane |

|||

|

1970s photograph of the 'Butters' Mould Breaking Crane (Photograph Courtesy of Doug Williams & Phil O'Brian) |

|||

|

Charging the 'Worn Out' Ingots - 1967 Doug Williams' father Jack (left) laying the gelignite in the ingots. |

|||

|

Firing the Charges! - Late 1950's / Early 1960's Here we see a plume of water gushing high into the sky after the explosive charges were detonated to break-up the old ingot moulds.

Also,on the right hand side of the photo can be seen some old buildings of the Dowlais steelworks and also the remains of the Dowlais steelworks coal washery, on the left of the 'Butters' crane, and in the distance, can be seen the shining roof of the Ifor works clay mill. The clay was made from crushed shale and used to re-line the furnaces. Some of the clay was also sold to other iron and steelworks.

Shale is a fine grained sedimentary rock composed of mud that is a mix of flakes of clay materials and tiny fragments of other minerals (Information Courtesy of Doug Williams) |

|||

|

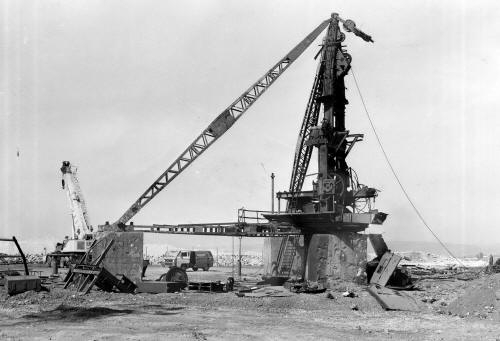

Butters Crane being dismantled - May 1987 (Photograph courtesy of the John Owen Collection) |

|||

|

Do you have any photographs or information for this page? If so, please email us, by clicking the 'Contact Us' button. |

|||

|

|

|||

|

To Dowlais Ifor Works |

|||

|

|